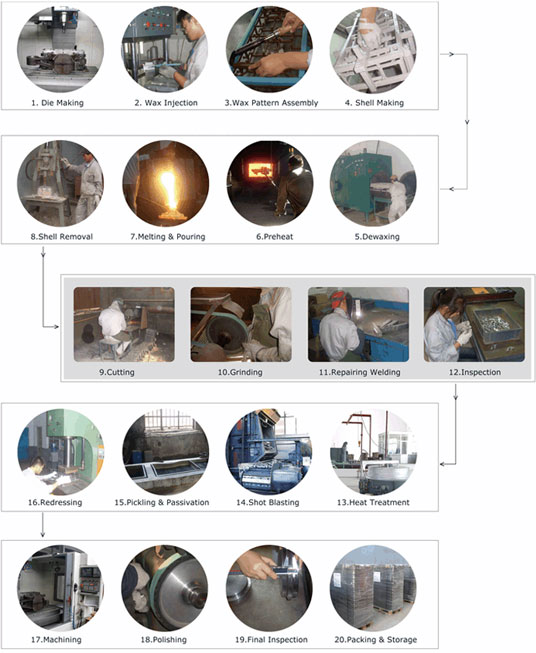

Wax Injection

The process begins with production of a heat disposable pattern. This pattern is usually made by injecting wax into a metal die or mold. Pattern is injected in Horizontal Automatic Injection Machine.

Pattern Assembly

The wax patterns are attached by the gate to a central wax runner system. The runner system is called a sprue. Patterns, runners, and pouring cup compromise the cluster or tree. Radius is provided to all joints between pattern and runner. Same checked thoroughly before coating to avoid rejection due to sand inclusions.

Shell Building

The shell building technique involves dipping the assembly into a ceramic slurry and then into a bed of extremely fine sand. After drying,, the process is repeated. Up to 4 to 6 layers may be applied in this manner.

Dewax Operation

The completed shell is placed in a steam autoclave where the pattern melts and runs out through the gates and pouring cup.

Firing the Shell Mold (Preheat)

The ceramic shell molds must be fired to burn out the last traces of pattern material and to preheat the mold in preparation for casting, usually in the range of 800 to 1100 degrees centigrade.

Casting

The preheated shell is filled with molten metal by gravity pouring. As the metal cools, the parts, gates, sprue, and pouring cup become one solid casting.

Shell Removal (Knockout)

After the metal solidifies and cools, the ceramic shell is then removed by vibratory methods or water blasting.

Shot Blasting

Casting to be shot blasted to remove all small ceramic particles.

Casting Removal (Cut Off)

Individual casting is removed from the cluster by means of a cut off wheel or welding cutting.

Finishing Operation (Gate Grinding)

Remaining gate protrusions are removed by belt grinding.

Heat Treatment

Casting is heat treated as per specifications.

Final Finishing

Finally casting is sand blasted or glass bead blasted as per customer requirement, packed as per customer specification and dispatched. |